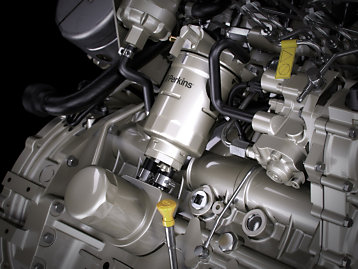

Engine optimisation and integration

By working with OEMs from the earliest planning stages, we find the best solution for you, however compact or unusual your application.Our unique approach means we’ll make a product that matches your application, delivering a more productive machine that enjoys a lifetime of low costs.

Our unique approach means we’ll make a product that matches your application, delivering a more productive machine that enjoys a lifetime of low costs.

The power of technology integration

Reducing time to market and minimising development costs are vital priorities for every Original Equipment Manufacturer (OEM) when launching new machines. The Technology Integration Workshop (TIW) programme is a unique collaborative concept developed by Perkins that sees our experts work side by side with you as the OEM to make engine integration more effective.

Learn more

The potential of engine downsizing

Can we achieve the same or better performance by integrating a smaller engine into our machines? This is the fundamental question that underpins the steady increase in Original Equipment Manufacturers (OEMs) looking at engine downsizing as a way of improving the cost-effectiveness of their operations.

Learn more